2025-11-10T11:04:49

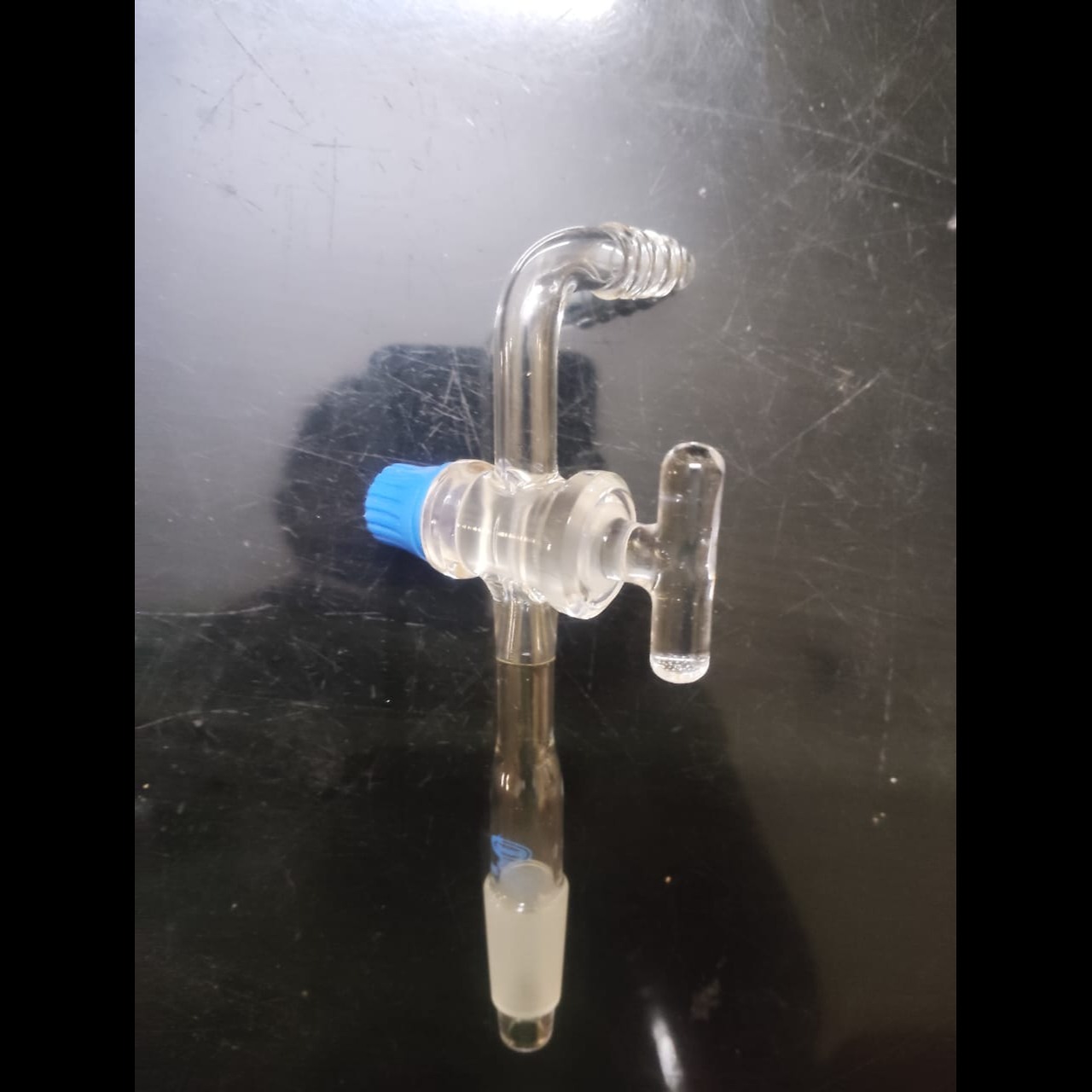

An adapter with a right-angle connection and a glass stopcock is a laboratory piece of glassware that allows for connecting two different pieces of equipment at a 90-degree angle. The right-angle connection provides a physical bend, and the glass stopcock is a valve on a sidearm that enables control over liquid or gas flow into or out of the connected apparatus. This setup is commonly used in distillation and other chemical processes to regulate flow. Features and specifications Function: Connects laboratory glassware with a right-angle bend, and the stopcock allows for flow regulation. Material: Typically made from borosilicate glass for heat resistance and durability. Connection type: Main body: Usually features a ground glass joint (cone) to connect to a primary piece of glassware. Sidearm: Has a glass stopcock to control flow. The other end is often a stem or tube for attaching flexible tubing. Stopcock details: The stopcock can be a glass plug or needle valve, with a size that can vary depending on the adapter. Joint sizes: Available in various standard sizes, such as 14/2314 / 2314/23, 19/2619 / 2619/26, 24/2924 / 2924/29, and 29/3229 / 3229/32 (cone sizes). Variations: Some adapters can be made with a PTFE (polytetrafluoroethylene) plug or needle valve stopcock instead of a glass one, and they may also be available with a straight connection instead of a right-angle one. The primary purpose of this adapter is to facilitate complex, modular laboratory setups by: Controlled Addition/Removal: Allowing the controlled addition of liquids (e.g., in a dropping or separating funnel setup) or gases into a reaction system, or the controlled withdrawal of samples or products. Flow Management: Providing a reliable mechanism to switch, isolate, or divert fluid streams within an apparatus, which is essential for procedures like distillation, filtration, and gas handling. System Integration: Bridging different components (e.g., connecting a condenser to a receiving flask, or adding a gas inlet to a reaction flask) while optimizing space and layout due to its right-angle design. Vacuum/Gas Handling: Ensuring an airtight seal is crucial for applications involving vacuum lines or inert gas environments (e.g., working with argon or nitrogen).

Have a question? Ask here!

Required fields are marked *